BEMCOT Wiper

Origins

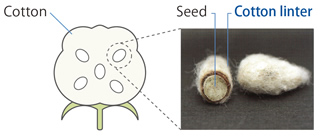

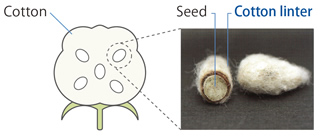

BEMCOT cleanroom wipers are produced from Bemliese,the

100% pure “cupro” cellulosic nonwoven derived from cotton

linter-the fine,downlike fiber that naturally protects and

cushions the seed of the cotton plant.

Cotton linter from around the world is transformed to pure

cellulosic nonwoven sheets in an integrated process unique

to the Bemliese plant of Asahi Kasei Fibers.

An ISO 9001 certified production facility located at Nobeoka

City in Japan.

Production Process

1. Linter refining

1. Linter refining

Multistage refining and purification of the cotton linter by steaming and washing.

2. Linter dissolution

2. Linter dissolution

Highly purified linter dissolved in a fine, pure, specially formulated spinning solution.

3. Filament spinning

Extrusion of the spinning solution from multi-orifice dies, to obtain multiple continuous filaments

4. Nonwoven sheet formation

Layering of the mutually self-bonding continuous filaments onto a mesh conveyor, to obtain nonwoven sheet without binder.

5. Rinsing, drying, roll winding

Mesh conveyor transport of the nonwoven sheet through water rinse and thermal drying, followed by take-up and roll winding.

The result is the fine, pure Bemliese nonwoven fabric, produced and processed in a clean plant environment, with a broad range of fabric patterns for optimal performance in specific fields of application.

Important features

•Free of binder

•Each continuous filament is self-bonded